Interestingly, the industries are at work concerning advancements in manufacturing and engineering in turn with the application modernization under the execution of Vision 2030 and present infrastructure availability. High-precision metalworking is one among many high-end requirements in the expansion process, in which metal lathe tools play an extensive part. These tools are demanded for the manufacture of finely intricate parts and components across major industries such as aerospace, automotive, energy, and construction. With this article, we will learn why metal lathe cutting tools for high-precision metalworking are significant for Saudi Arabia.

1. Excellent in shape forming complex parts

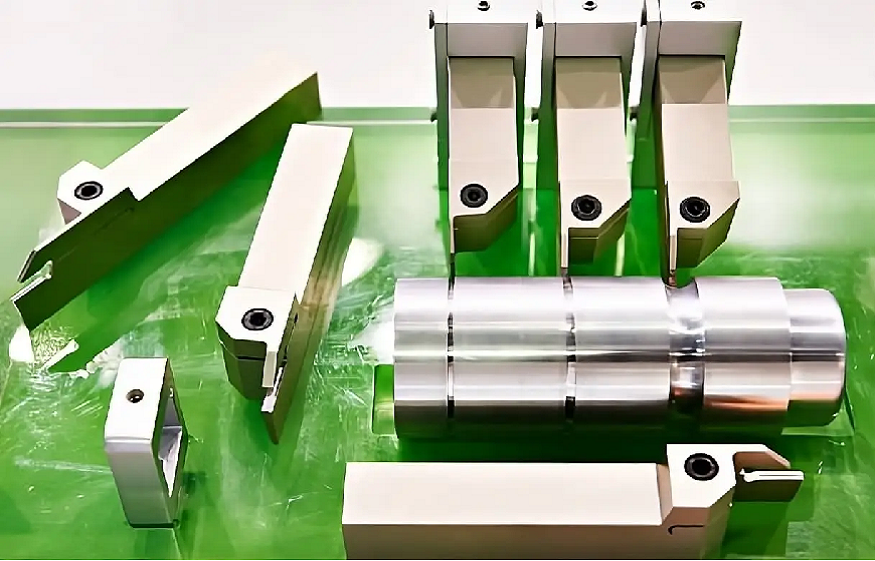

High in precision shaping metals, metal lathe tools make possible the formation of complex geometric shapes like cylindrical, conical, and spherical. Such precision is highly valued in the aerospace and automobile industries since even small variations affect performance. Increasingly having such demands commercially in the kingdom, these tools ensure manufactured parts meet high-quality specifications demanded both nationally and internationally, thus making them indispensable for even the most stringent standards in manufacturing.

2. Versatility in the Manipulation of Materials

Metal lathe tools are versatile because their range of materials includes steel, aluminium, titanium, and harder alloys like Inconel and Hastelloy. For example, Saudi Arabia’s industrial landscape is so diversified that metalworking must use different materials, all having their special properties. Cutting techniques using lathe tools adapt to different materials, optimizing machining for more precise and cost-effective processes. The use of such tools makes it easy for the manufacturers to respond to the challenge of property variations in the various materials and machining requirements for feeder and column components, thus leading to a successful operation.

3. Enhanced Surface Finish Quality

Finishing up with a high quality is important for functional and aesthetic purposes. Surface finish is important when it comes to metal lathe tools because it helps in achieving very smooth and polished finishes that become important in various industries, such as automotive manufacturing, to determine the efficiency of the operation of the component. Besides, Saudi Arabia is a high-standard country when it comes to manufacturing, especially in terms of trade. Such tools help keep the products at pace with local and international standards. In addition, a really good surface finish contributes much time to the efficiency and longevity of the final product.

4. Productivity and Efficiency are greatly increased.

They increase productivity in metal-working operations with the use of metal lathe tools. As these are now available at high speed, an outline portion of the mass of the part is quickly produced at the cost of precision and quality consistency. In Saudi Arabia, every moment counts to meet the demand of the market; with production cycles shortened by metal lathes, the output is increased, contributing to a competitive edge for businesses involved in large-scale manufacturing. These time reductions make it easier for manufacturers to respond better to changing customer needs and market conditions.

5. Customization of Components

Metal lathe tools provide flexibility in customization. They can be adjusted in terms of cutting tools, feeds, and speeds to manufacture according to demand. This is important most certainly for custom-made components in oil and gas industries, where they may not need thousands of units. Saudi Arabia, the world’s leading oil country, enjoys this in that it’s now easy to come up with custom components to meet industry requirements. In fact, customization can ensure that manufacturers can respond to niche as well as more complex needs since the equipment can accommodate most requirements.

6. Reduction of Material Wastage

With metal lathe tools, the wastage of material is lessened, owing to their high levels of accuracy and control over the cutting process. This is usually much better for industries such as aerospace, automotive, and petrochemicals, where the high-quality components are manufactured from costlier sources. In Saudi Arabia, waste reduction accounts for billion-dollar savings and maximized efficiencies in the managerial approaches to resource management, translating into operational effectiveness. Also, it contributes to sustainability in the event of reduced excess material disposition.

7. Higher Accuracy in Greater Small Tolerances

It is through metal lathe tools that extremely tight tolerances can be worked, sometimes producing parts with measurements within thousandths of an inch, or a micrometre. Such precision is necessary for the high-tech increasingly sectors such as aerospace and defence in Saudi Arabia where failure can mean the safety or functionality of parts relying on precision-engineered parts. This allows the manufacture of high-performance components that can withstand rigorous conditions. As industry designs become more sophisticated and demanding, matching these with tighter tolerances ensures that the final product is of better quality and will give better reliability.

8. Reduced Requirement for Post-Processing

Precision in metal lathe tools significantly reduced post-processing steps like grinding, polishing, or finishing. This saves time and cuts down on costs that are related to the additional machining processes. In Saudi Arabia where speed and efficiency are vital, the resulting decrease in post-processing speeds up production and gives those companies the ability to produce high-quality products faster. Less post-processing further avoids the chances of errors, preserving the integrity and intactness of components.

9. Improved Tool Longevity and Durability

Modern metal lathe tools are made from durable high-speed steel, carbide, and ceramic materials, which can withstand the severe conditions that apply to the machining of hard metals. Such durability is a necessity, especially for companies in Saudi Arabia, where downtime and replacement costs must be minimized. Although the prices are high, getting high-quality lathe tools guarantees a service life longer than the price, hence making them a cost-effective solution over time. Furthermore, long tool life contributes to consistent performance, which, in turn, creates production efficiency.

10. Prevention of Automation and Integration into CNC

The inclusion of CNC systems with metal lathe tools has made precision machining possible. CNC metal lathes provide such an automated high cut consistent operation that no other machine can deliver. Moreover, with CNC capabilities, the fight toward the digital arena in Saudi Arabia can operate even at odd hours; thus, forming labour cost reductions while boosting production efficiency that accompanies new manufacturing environments. CNC technology also enhances the flexibility and scalability of production, meeting growing demand with ease.

Metal lathe tools are indispensable for precision engineering metalworking; they primarily confer the necessary accuracy, versatility, and efficiency that modern manufacturing environments require. Given the high growth rates in manufacturing as well as the increasing requirements for precision-engineered parts by cutting tools equipment providers in Saudi Arabia, these instruments are very critical in improving their client’s competitiveness. It minimizes material loss and automates production, essential avenues through which high-performance components are produced. As Saudi Arabia continues to spend on technological advancement and industrial diversification, the role of metal lathe tools becomes increasingly important in market demand satisfaction.